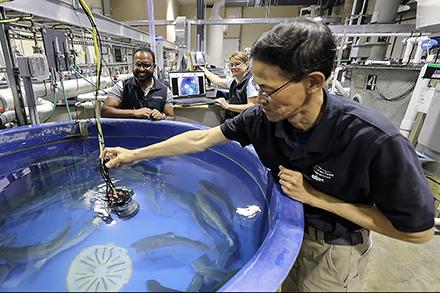

ARS Innovations Help Combat Food Loss and Waste

Food loss and waste is a monumental problem and while the Agricultural Research Service does not receive direct funding for food loss and waste programs, research is a critical factor for finding innovative, sustainable solutions for the food loss and waste problem.

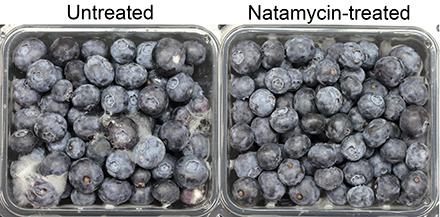

Take a look at a sampling of ARS's innovative research some of which has already been introduced in the marketplace including projects to improve growing practices, breed fruit and vegetables that can better handle storage and transportation, find environmentally friendly alternatives to pesticides and sprays, develop new technologies to make processing and delivery more efficient, and turn post-harvest waste into usable foods and materials, including biofuels.

[Back to Innovations for Reducing Food Loss and Waste]